Certificação de cabo de rede de terceiros: O que você precisa saber

18 de setembro de 2024 / Geral, fundamentos de aprendizado, instalação e teste

Fabricantes respeitáveis promovem e etiquetam os cabos, os patch cords e o hardware de conexão como sendo “certificados por terceiros”, “verificados” ou “listados”. Isso significa que um fabricante determinou de modo independente que seus produtos estão em conformidade com os padrões da indústria. O que exatamente significam essas certificações? Como elas diferem da certificação de cabos de uma planta de cabeamento instalada? Vamos dar uma olhada.

O que é certificação de cabo?

O dicionário define “certificação” como o reconhecimento formal de que algo possui certas qualificações ou atende a certos padrões. O teste de certificação faz exatamente isso: determina se o cabeamento está em conformidade com uma categoria ou classe específica de cabo, de acordo com os parâmetros de desempenho descritos nos padrões de cabeamento da indústria ANSI/TIA-568 ou no padrão ISO/IEC 11801.

Porém, o termo “certificação de cabo” pode ter significados diferentes para pessoas diferentes.

- • Os fabricantes podem proclamar que seus cabos são certificados como estando em conformidade com padrões da indústria. A certificação por terceiros, como a certificação ETL da Intertek, indica que o cabo é certificado como atendendo aos padrões de componentes da indústria.

- • A certificação de cabo também pode se referir ao teste de certificação dos links instalados para determinar sua conformidade com os padrões da indústria, como determinar se um link da Categoria 6A instalado está em conformidade com os parâmetros TIA-568 em termos de comprimento, perda de inserção, perda de retorno, diafonia de extremidade próxima (NEXT), soma de potência NEXT, diafonia de extremidade distante de nível igual (ELFEXT), relação atenuação-diafonia (ACR) e muito mais.

A distinção entre o “cabo certificado” de um fabricante e o teste de certificação é que o teste ocorre após a instalação da planta de cabeamento. O teste de certificação é obrigatório para a obtenção da garantia do sistema e é essencial para garantir que o cabeamento foi instalado corretamente. O teste de certificação também documenta os resultados do teste de todos os links, o que pode auxiliar na resolução de problemas posteriores ou ajudar os instaladores a protegerem suas empresas, mostrando que o cabeamento passou no teste de certificação no momento da instalação.

O que é certificação por terceiros?

Os componentes podem ser certificados pelos primeiros, o que significa que o próprio fabricante está declarando que seus produtos atendem aos critérios que foram definidos para aquele produto. (Isso é confiável?) Os produtos também podem ser certificados por segundos, o que geralmente indica que uma empresa (talvez o usuário ou o instalador) criou seu próprio programa de certificação e seus produtos atendem aos critérios identificados por aquele programa (ainda parece um pouco suspeito).

Por outro lado, a certificação por terceiros indica que um produto foi certificado por um organismo de certificação independente e credenciado como estando em conformidade com os padrões específicos de segurança, qualidade ou desempenho da indústria.

Quando os produtos são certificados por terceiros, o órgão certificador realiza o teste aleatório dos produtos em seu laboratório de teste credenciado com base em padrões ou regulamentações reconhecidos pela indústria. O teste por terceiros é um processo demorado e caro para os fabricantes; é um custo e um prazo conhecido, incluídos no orçamento e no cronograma de lançamento de qualquer produto novo. Os fabricantes também pagam taxas anuais para manter a certificação de um produto e podem esperar inspeções periódicas para garantir conformidade constante.

Quais são as vantagens da certificação por terceiros?

Para manter os custos reduzidos, os fabricantes projetam seus produtos tendo em mente os requisitos de certificação. Alguns certificadores terceirizados oferecem consultas pré-teste durante o processo de projeto, e os fabricantes podem optar por pagar por esses serviços para garantir que seus produtos finais passem no grande teste na primeira tentativa. A certificação de terceiros também significa que qualquer modificação em um produto deve ser submetida a novo teste e recertificação, o que significa mais tempo e dinheiro.

Com todo o custo e tempo envolvidos, por que os fabricantes optam por passar por esse processo?

Primeira e principalmente porque, muitas vezes, isso é exigido por lei para vender ou instalar um produto em uma determinada região; nesse caso, os fabricantes não têm escolha. Os outros motivos para a certificação por terceiros são: ganhar a confiança do consumidor, permitir que os produtos sejam imediatamente aceitos no mercado e demonstrar que o fabricante tomou as medidas adequadas para garantir que você esteja adquirindo um produto seguro e eficaz.

Tipos de certificação por terceiros

Em nossa indústria, os componentes de cabo são certificados por terceiros quanto à segurança e ao desempenho. Em termos de segurança, os produtos normalmente são “listados”, o que geralmente é um requisito imposto pelas autoridades competentes (AHJs). Por outro lado, “verificado” indica desempenho da transmissão elétrica.

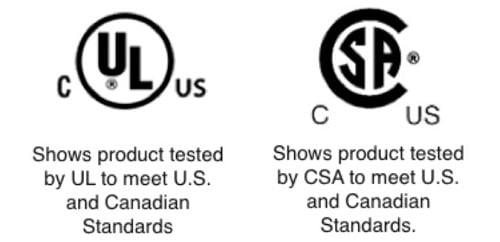

Na América do Norte, uma listagem do Underwriters Laboratories (UL Solutions) assegura que os componentes de cabeamento atendem aos requisitos de segurança de acordo com o Código Elétrico Nacional (NEC), como características de fumaça e chamas. Essas listagens determinam se um cabo é classificado como riser (CMR) ou plenum (CMP); cabos colocados no espaço plenum (manejo de ar) usado para circulação de ar devem impedir a propagação do fogo ou a liberação de fumaça tóxica. Da mesma forma, uma listagem do CSA Group (anteriormente Canadian Standards Association) indica que um produto atende ao Código Elétrico Canadense (CEC). As listagens CE e UL são praticamente intercambiáveis, e uma listagem “CSA-US” ou “c-UL” indica que o produto atende aos padrões dos EUA e do Canadá.

A União Europeia exige a listagem CE (a marca CE) para indicar que um produto atende a todos os requisitos de saúde, segurança e meio ambiente. Outras partes do mundo reconhecem as certificações UL, CSA e CE, mas alguns países podem ter listagens de segurança específicas, como a marca PSE no Japão ou a marca SNI na Indonésia.

Outra certificação de cabos comum em nossa indústria é a certificação ETL do Intertek. O Intertek é considerada um Laboratório de Teste Reconhecido Nacionalmente (NRTL) como o UL. Ao “listar” um produto para demonstrar que ele atende aos padrões mínimos de segurança, o Intertek testa segundo os padrões do UL. A única diferença real entre as duas listagens é o laboratório de teste que as respalda.

Os produtos também podem ser “verificados” como ETL quanto à qualidade e ao desempenho, o que indica que o produto foi testado por terceiros para assegurar que atende aos padrões de desempenho ANSI/TIA, ISO/IEC, EN ou IEEE apropriados. Ao contrário das listagens, as verificações não são obrigatórias, porque o desempenho da transmissão elétrica não afeta diretamente a segurança humana. O que a verificação faz é garantir que o produto que você está instalando terá o desempenho necessário para dar suporte às aplicações de rede do seu cliente.

A Fluke Networks certifica cabos?

Pesquise no Google ou na Amazon e você verá um grande número de cabos e patch cords rotulados como “Fluke Certified” (Certificado pela Fluke). Mas, vamos esclarecer: A Fluke Networks NÃO certifica nem endossa componentes de cabeamento.

Fabricamos testadores de certificação para ajudar você a certificar que uma planta de cabos instalada atende aos padrões TIA, ISO/IEC e IEEE. Também fornecemos equipamentos de teste para outras empresas de certificação e outros fabricantes para uso em seus próprios laboratórios.

Mas, como fabricantes, nunca certificamos componentes de terceiros. Nossos próprios testadores são certificados por terceiros, listados em relação à segurança e verificados em relação ao desempenho. Na verdade, a Fluke Networks foi o primeiro fornecedor de equipamentos de teste a obter a verificação ETL de precisão IEC de nível V e ANSI/TIA-1152-A de níveis IIIe e 2G, o que significa que nossos testadores podem ajudar você a certificar sua planta de cabeamento de modo confiável.

Como não certificamos componentes de cabeamento, qualquer fornecedor que rotule seus componentes como "Fluke Certified" provavelmente está apenas dizendo que testou seus componentes com um testador Fluke. Somos gratos por eles estarem usando nossos equipamentos para testar seus componentes, mas essas alegações são propaganda enganosa. Sempre que vemos tais afirmações, tomamos medidas para que sejam reformuladas.

O valor dos relatórios de teste de certificação

Se você não conhecer algum fornecedor que esteja (falsamente) alegando ser "Fluke Certified" ou se ele simplesmente afirmar que seus componentes foram testados usando um testador da Fluke Networks, recomendamos que solicite o relatório de teste real da Fluke para verificar essas alegações. Você deseja o arquivo FLW nativo do LinkWare™ em vez de um relatório em PDF; os arquivos FLW são criptografados por segurança e não podem ser editados nem falsificados.

Por exemplo, os testadores de certificação da série DSX CableAnalyzer™ da Fluke Networks registram todos os valores numéricos de cada parâmetro para todo par de links e exibem os resultados graficamente em traços. Os relatórios de teste do LinkWare também mostram os limites de teste selecionados e o testador Fluke específico usado no teste, bem como a data da última calibração do testador e a versão do software.

Se um fornecedor apresentar a você um relatório de teste do LinkWare, será necessário entender como ler o relatório, saber que tipo de teste ele realizou e examinar cuidadosamente os resultados em relação às alegações feitas por ele. Só porque um fornecedor apresenta um relatório de teste mostrando uma APROVAÇÃO, isso não significa necessariamente que o cabo está em conformidade com os padrões da indústria ou que continuará assim após a instalação. Você tem que confiar na informação do fornecedor de que o relatório recebido se refere ao cabo que você de fato comprou.

Por exemplo, um fornecedor pode ter feito um teste simples de limite de terminação única em uma bobina de cabo de 1.000 pés, que informa a diafonia próxima e a perda de retorno, mas não determina a perda de inserção ou a diafonia distante. Por isso é essencial certificar todo link após a instalação, e é a única maneira de adquirir uma garantia do fornecedor.

Ferramentas de teste de certificação de cabo

O teste de certificação para obter a garantia do fabricante e assegurar a conformidade com os padrões de uma planta de cabos instalada só pode ser feito com um testador de certificação. Experimente os certificadores de cabos de cobre DSX CableAnalyzer da Fluke Networks e nossa família de testadores de certificação de fibra, como o CertiFiber® Pro para certificação de fibra nível 1, e o OptiFiber® Pro OTDR para certificação de fibra nível 2.

Testadores também estão disponíveis para o teste de verificação, que realiza o teste básico das funções de continuidade e qualificação, o que determina se o cabeamento é compatível com uma tecnologia ou com aplicações específicas (por exemplo, PoE, 10GBASE-T). Essas ferramentas são usadas principalmente em plantas de cabos existentes para verificar alterações na planta de cabos, garantir o desempenho de dispositivos novos e resolver problemas de rede. O Fluke Networks LinkIQ™ é um testador de rede fácil de usar que pode verificar e qualificar plantas de cabos instaladas.

Embora alguns recursos das ferramentas de teste sejam os mesmos, entender a diferença entre testes de verificação, qualificação e certificação, e quando realizar cada tipo de teste ajudará você a escolher a ferramenta certa para o trabalho.