Terminating a Category 6, 5e and 5 connector

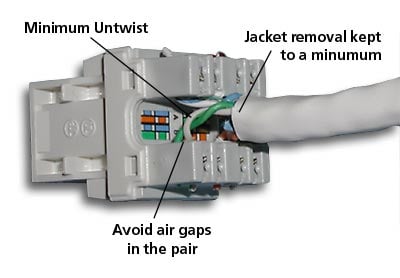

| ANSI/TIA/ 568-C.0 It is essential to maintain the design performance of connecting hardware when terminated to a balanced twisted-pair cable, and this shall be achieved by terminating the appropriate connecting hardware for that balanced twisted-pair cable in accordance with the connecting hardware manufacturer’s instructions. Where no connecting hardware manufacturer’s instructions exist, then the cable geometry shall be maintained as close as possible to the connecting hardware, and its cable termination points and the maximum pair un-twist for the balanced twisted-pair cable termination shall be in accordance with table 1. To maintain the cable geometry, remove the cable sheath only as much as necessary to terminate the cable pairs on the connecting hardware. The connecting hardware manufacturers instructions for cable sheath strip-back shall be followed. When terminating category 5e and higher cables, the cable pair twists shall be maintained to within 13 mm (0,5 in) from the point of termination. When terminating category 3 cables, the cable pair twists shall be maintained to within 75 mm (3 in) from the point of termination. For best performance, when terminating cable on connecting hardware, the cable pair twists should be maintained as close as possible to the point of termination. In reality, if you allow the installer to have 13 mm (0,5 Inch) untwist, the performance of the cabling system will be reduced. On short links, that could result in a failure. You should aim for no untwist in the pairs for Category 6 as shown below:  Editors comment: Some customers feel that this is unrealistic. We know what it takes to achieve a PASS, and this one critical element to ensure that. Cenelec EN50174 Part 2 The connecting hardware used for copper cabling shall be installed to provide minimal signal impairment by preserving wire pair twists as closely as possible to the point of mechanical termination (by not changing the original twist), see EN 50173. In addition only a minimum of cable jacket shall be removed. Will adding extra twists degrade the performance? No, despite what it says above - by not changing the original twist. You will always find that one of the pairs does not have a tight twist. On occasions its almost impossible to keep the twist to the IDC. Adding an extra twist in that pair will not only improve NEXT, but Return Loss as well. Try it for yourself. Particularly important for block wiring with SYSTIMAXs 110 IDC and TEs Ultimate. Don't overdo it, though. Be careful that you dont cause one wire in the pair to wrap around the other wire while the latter remains relatively straight. You'll introduce NEXT and may cause a failure. |